It is the direct labor plus any manufacturing overheads needed to convert raw materials into a finished product. Therefore, managers need to be careful and critical when choosing and using allocation bases and rates to calculate manufacturing overhead costs. They should also monitor and evaluate the results and make adjustments as needed to ensure that the cost of conversion is accurate and fair.

What Is The Conversion Cost Formula?

During a month, Company B spends $55,000 on direct labor and $66,000 on plant overhead. This is the cost of directly manufacturing the product, such as wages, salaries to workers, pension funds for workers, production staff insurance, supervision, and so on. The management team wants to reduce the time it takes to produce each widget to increase overall output.

![]()

Days Sales In Inventory

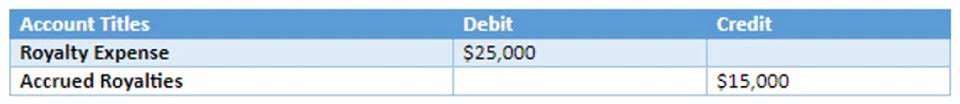

By using these metrics, managers can monitor and control the production costs and optimize the resources. They can also compare the conversion costs and per unit costs of different products, departments, or periods, and identify the Suspense Account areas of improvement or inefficiency. Conversion cost is a useful tool for cost accounting and management, and it can help to improve the performance and profitability of any business. In a given period, the company incurs $10,000 in direct labor costs and $15,000 in factory overhead costs.

- The cost of goods manufactured, on the other hand, reflects the total amount of resources consumed by the production process during a period, regardless of the product or batch differences.

- Remember, these are just some of the key aspects related to the Cost of Conversion.

- For instance, assembly line workers, machine operators, and quality control personnel contribute to the conversion process.

- To find the profits related to specific products, it is important that the costs of these products are known.

- Finally, the factory overheads are also considered when calculating the conversion cost of the chair.

How to Calculate Conversion Cost in Manufacturing

Be the first to receive exclusive offers and the latest news on our products and services directly in your inbox. The iron, aluminium, and SBR tyres expenses are considered raw material charges in the example. Based on the costs provided above, calculate the conversion of Company A. Local SEO, or local search engine optimization, is a crucial aspect of digital marketing that… In today’s interconnected world, where businesses heavily rely on technology https://www.bookstime.com/ and the internet to… So, the main difference between CPC and CPA is that CPC focuses on converting a lead into a customer, while CPA focuses on the cost of acquiring a customer.

- Overhead costs are the indirect costs that are not directly traceable to a specific product or process, such as rent, utilities, depreciation, and insurance.

- Instead, they use different costing models that focus on the cost of services rendered, where labour and overheads are the primary components, but the prime/conversion distinction is not relevant.

- The $7 material costs that do no relate to the production of the bicycle are not considered.

- The computational responsibility lies with the factory manager who collects the relevant data, calculates the prime cost figure for the period and reports the same to operations manager for review.

How to Calculate the Average Cost of Converting One Unit of Product?

The best methods for reducing conversion costs involve improving efficiency that reduce both direct labor and manufacturing overhead. Through cost of conversion analysis, they identify that a significant portion of their labor costs is attributed to a specific production stage. By implementing process improvements and automation in that stage, they can reduce labor costs and enhance overall efficiency. The primary costs conversion cost formula for making the table include both the cost of the furniture maker’s labor and the raw materials needed to build the table, such as lumber, hardware, and paint. Remember, these are just a few strategies to improve conversion cost efficiency. As can be seen from the list, the bulk of all conversion costs are likely to be in the manufacturing overhead classification.